When flawless cleaning, precise deburring, gentle paint removal, or an impeccable cosmetic finish is required on delicate, high-precision, or high-value components without any risk of distortion, particle embedding, or airborne dust, wet blasting (also called slurry blasting or vapor honing) consistently proves to be the superior choice.

What Exactly Is Wet Blasting and How Does the Process Function?

Wet blasting combines fine abrasive media with water to create a flowing slurry that is accelerated through dedicated nozzles under controlled pressure. A microscopic water film envelops each abrasive particle, serving as both lubricant and shock absorber. This dramatically reduces impact force compared to conventional dry blasting, enabling aggressive material removal while fully protecting even the most sensitive substrates from warping, overheating, or surface damage.

At the same time, the water instantly eliminates dust formation, continuously rinses away contaminants, and dissipates process heat, resulting in an exceptionally clean, cool, and operator-friendly working environment.

Why Wet Blasting Consistently Outperforms Traditional Dry Methods

The process is extraordinarily gentle yet remarkably powerful, making it the first choice for thin-walled, highly polished, soft, or brittle materials such as aluminum, titanium, brass, copper, mirror-finish stainless steel, plastics, and advanced composites. It operates in an almost completely dust-free manner, dramatically improving workplace safety and eliminating the need for elaborate extraction systems.

Wet blasting creates the highly desirable smooth, non-directional, satin-to-semi-gloss finish prized in luxury goods, medical devices, and premium consumer products. The protective water layer significantly extends media life and reduces abrasive consumption, while still delivering precise deburring on complex machined parts without creating secondary burrs. It is uniquely capable of safely processing materials that produce explosive, flammable, or toxic dry dust, including magnesium, carbon fiber, and certain coatings. Finally, it prepares surfaces with an ideal micro-roughened profile that ensures outstanding adhesion for subsequent painting, powder coating, plating, or anodizing.

Components and Industries That Gain the Greatest Advantage

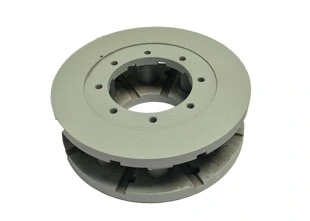

Aerospace manufacturers rely on wet blasting for turbine blades, engine components, and landing-gear parts. The medical and dental sectors use it for implants, surgical instruments, and orthopedic devices. Automotive and electric-mobility production lines treat aluminum housings, battery trays, and decorative trim. Luxury and consumer-goods producers finish watch cases, jewelry, smartphone frames, and high-end sanitary fittings. Precision engineering facilities process dies, molds, and tight-tolerance gears, while restoration specialists gently strip paint from classic vehicles and motorcycles.

State-of-the-Art Wet Blasting Systems for Absolute Consistency

Contemporary Roster wet blasting equipment elevates performance through robot-guided or CNC-controlled nozzles that follow precise programmed paths, guaranteeing perfectly uniform results even on the most intricate geometries. Fully automated loading and unloading solutions, ranging from rotary indexing tables to inline conveyor integration and complete robotic cells, enable seamless incorporation into modern production lines. Integrated closed-loop water treatment and automatic slurry-concentration management maintain stable process parameters and keep operating costs low while delivering repeatable high-quality outcomes shift after shift.

Power and Gentleness in Perfect Harmony

Wet blasting uniquely combines aggressive cleaning and finishing capability with extraordinary gentleness, all within a virtually dust-free and environmentally responsible process. Whether the task is deburring fragile medical implants, restoring an elegant satin appearance on luxury watch components, safely stripping coatings from aerospace assemblies, or preparing lightweight electric-vehicle parts for flawless bonding, wet blasting accomplishes every objective faster, safer, and with superior aesthetic results compared to any dry blasting technique.

If you are ready to eliminate dust, slash media costs, and consistently achieve stunning finishes on your most demanding workpieces, wet blasting from Roster is the professional solution that transforms surface-finishing challenges into clear competitive advantages.

English

English