Hanger type shot blasting machines are a crucial part of many industries, including automotive, aerospace, and construction. They are used for cleaning, strengthening, and polishing metal surfaces. But what is the science behind these machines? How do they work, and what makes them so effective? This article will delve into the inner workings of hanger type shot blasting machines.

The Basic Principle

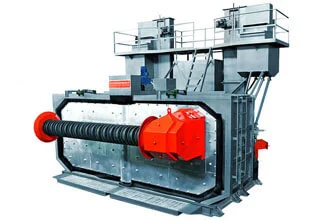

The basic principle behind a hanger type shot blasting machine is quite simple. The machine uses a wheel to propel small steel shots or grits at high speed towards the surface of the workpiece. This process removes contaminants, scales, and rust, leaving the surface clean and ready for further processing.

The Hanger System

What sets the hanger type shot blasting machine apart from other types is its unique hanger system. The workpieces are hung on a hanger or hook, which rotates and moves inside the blasting chamber. This ensures that all sides of the workpiece are evenly blasted, resulting in a uniform finish.

The Blasting Process

The blasting process in a hanger type shot blasting machine is highly efficient. The machine is equipped with multiple blast wheels, each propelling thousands of shots per minute. The high-speed shots strike the surface of the workpiece, dislodging any contaminants and creating a rough surface that is ideal for painting or coating.

The Dust Collection System

A hanger type shot blasting machine also includes a dust collection system. This system collects the dust and debris generated during the blasting process, keeping the working environment clean and safe. The collected dust can then be safely disposed of, reducing the environmental impact.

The Cost-Effectiveness

Despite the advanced technology and high efficiency, a hanger type shot blasting machine price is quite reasonable. This, combined with the machine’s low maintenance needs and high productivity, makes it a cost-effective solution for surface treatment.

In conclusion, the science behind hanger type shot blasting machines lies in their simple yet effective principle, unique hanger system, efficient blasting process, dust collection system, and cost-effectiveness. If you’re looking for a reliable hanger shot blasting machine, consider Roster, one of the leading shot blasting machine manufacturers. We offer high-quality, durable, and efficient automatic shot blasting machine that can meet all your surface treatment needs.

As a professional steel grit manufacturer, Roster offers a wide range of top-quality surface treatment equipment for various applications. Popular products provided by Roster are as follows:

Preservation Lines

Beam Shot Blasting Machine

Sand Blasting Booth for Sale

Tumble Belt Shot Blasting Machine

Wire Rod Shot Blasting Machine

Gas Cylinder Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Shot Blasted Stainless Steel

Feed Spout

Rolling Drum Shot Blasting Machine

Sandblasting Machine for Sale

Control Cage

Table Type Shot Blasting Machine

Cylinder Shot Blasting Machine

English

English